您當(dāng)前位置:主頁 > 產(chǎn)品中心 > 進(jìn)口閥門 > 美國進(jìn)口閥門 >

類別:美國進(jìn)口閥門 ? 發(fā)布時間:1970-01-01 08:00 ? 瀏覽: 次

進(jìn)口襯氟止回閥描述--

ALSO進(jìn)口襯氟止回閥是一種自動閥,只允許介質(zhì)向一個方向流動,而且阻止流體倒流,在一個方向流動的壓力作用下,閥瓣打開,流體反方向流動的壓力和閥瓣,PTFE閥球的自重,作用于閥座,從而切斷流動

進(jìn)口襯氟止回閥優(yōu)點--

水平安裝、垂直安裝等結(jié)構(gòu)

介質(zhì)所能達(dá)到的地方全部采用襯里工藝,而各種腐蝕

摩擦小,潤滑性能好,防污、防粘、防靜電;

產(chǎn)品連接件少,整體鋼性好。

進(jìn)口襯氟止回閥材料明細(xì)表--

| 壓力 | 1.0MPa 1.6MPa 150LB | |||

| 序號 | 名稱 | 材料明細(xì) | ||

| 1 | 閥體、閥瓣、閥蓋 | A216 WCB+襯里材質(zhì) | A351 CF8/A351 CF8M+襯里材質(zhì) |

A351 CF3 /A351 CF3M +襯里材質(zhì) |

| 2 | 球 | PTFE | ||

| 3 | 襯里材質(zhì) | FEP PFA GXPO | ||

| 4 | 螺栓 | A193 B7 | A320 B8 | A193B8M |

進(jìn)口襯氟止回閥技術(shù)性能規(guī)范-

| 設(shè)計標(biāo)準(zhǔn) | HG/T 3704, GB/T 12235 | API 6D | ||

| 結(jié)構(gòu)長度 | HG/T 3704, GB/T 12221 | ASME B16.10 | ||

| 法蘭形式尺寸 | HG/T 20592, GB/T 9119 | ASME B16.5, JIS B2220 | ||

| 檢驗與試驗 | GBT 13927, JB/T 9092 | API 598 | ||

| 公稱壓力( MPa) | 1.0 | 1.6 | 150Lb | |

| 實驗壓力( MPa) | 殼體試壓 | 1.5 | 1.5 | 1.5 |

| 高壓密封 | 1.1 | 1.1 | 1.1 | |

| 低壓密封 | 0.6 | 0.6 | 0.6 | |

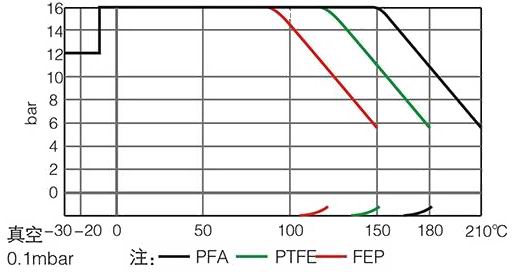

| 適用溫度(℃) | PFA: -30~200 FEP -30~150 GXPO -10~80 | |||

| 適用介質(zhì) | 鹽酸、硝酸、氫氟酸、液氯、硫酸、王水等強(qiáng)腐蝕性介質(zhì) | |||

進(jìn)口襯氟止回閥壓力溫度曲線圖--

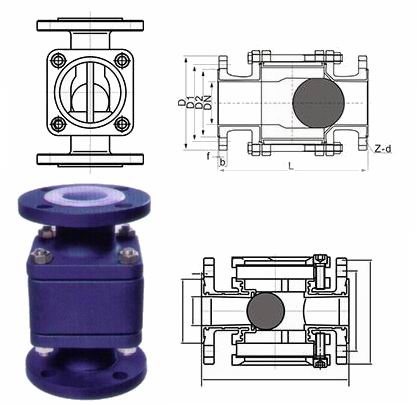

進(jìn)口旋啟式襯氟止回閥外形尺寸--

HG/T 20592 PN10 (單位:mm)

| DN | L1 | L2 | D | D1 | D2 | Z-d | f | b |

| 15 | / | 130 | 95 | 65 | 45 | 4-14 | 2 | 14 |

| 20 | / | 150 | 105 | 75 | 55 | 4-14 | 2 | 14 |

| 25 | / | 160 | 115 | 85 | 65 | 4-14 | 2 | 14 |

| 32 | / | 180 | 140 | 100 | 78 | 4-18 | 3 | 16 |

| 40 | / | 200 | 150 | 110 | 85 | 4-18 | 3 | 16 |

| 50 | 43 | 230 | 165 | 125 | 100 | 4-18 | 3 | 16 |

| 65 | 46 | 290 | 185 | 145 | 120 | 4-18 | 3 | 18 |

| 80 | 46 | 310 | 200 | 160 | 135 | 4-18 | 3 | 20 |

| 100 | 52 | 350 | 220 | 180 | 155 | 8-18 | 3 | 20 |

| 125 | 56 | 400 | 250 | 210 | 185 | 8-18 | 3 | 22 |

| 150 | 56 | 480 | 285 | 240 | 210 | 8-23 | 3 | 24 |

| 200 | 60 | 495 | 340 | 295 | 265 | 8-23 | 3 | 26 |

| 250 | 68 | 550 | 395 | 350 | 320 | 12-23 | 4 | 28 |

| 300 | 78 | 620 | 445 | 400 | 368 | 12-23 | 4 | 28 |

| 350 | 78 | 720 | 505 | 460 | 428 | 16-23 | 5 | 28 |

HG/T 20592 PN16

| 15 | / | 130 | 95 | 65 | 45 | 4-14 | 2 | 14 |

| 20 | / | 150 | 105 | 75 | 55 | 4-14 | 2 | 14 |

| 25 | / | 160 | 115 | 85 | 65 | 4-14 | 2 | 14 |

| 32 | / | 180 | 140 | 100 | 78 | 4-18 | 3 | 16 |

| 40 | / | 200 | 150 | 110 | 85 | 4-18 | 3 | 16 |

| 50 | 43 | 230 | 165 | 125 | 100 | 4-18 | 3 | 16 |

| 65 | 46 | 290 | 185 | 145 | 120 | 4-18 | 3 | 18 |

| 80 | 46 | 310 | 200 | 160 | 135 | 8-18 | 3 | 20 |

| 100 | 52 | 350 | 220 | 180 | 155 | 8-18 | 3 | 20 |

| 125 | 56 | 400 | 250 | 210 | 185 | 8-18 | 3 | 22 |

| 150 | 56 | 480 | 285 | 240 | 210 | 8-23 | 3 | 24 |

| 200 | 60 | 495 | 340 | 295 | 265 | 12-23 | 3 | 26 |

| 250 | 68 | 550 | 405 | 355 | 320 | 12-25 | 4 | 28 |

| 300 | 78 | 620 | 460 | 410 | 375 | 12-25 | 4 | 29 |

| 350 | 78 | 720 | 520 | 470 | 435 | 16-25 | 5 | 34 |

ASME 816.5 Class150

| 1/2 | / | 130 | 89 | 60.5 | 35 | 4-16 | 2 | 12 |

| 3/4 | / | 150 | 98 | 700 | 43 | 4-16 | 2 | 12 |

| 1 | / | 160 | 108 | 79.5 | 51 | 4-16 | 2 | 12 |

| 1 1/4 | / | 180 | 117 | 89.0 | 64 | 4-16 | 2 | 13 |

| 1 1/2 | / | 200 | 127 | 98.5 | 73 | 4-16 | 2 | 15 |

| 2 | 43 | 230 | 152 | 120.5 | 92 | 4-19 | 2 | 16 |

| 2 1/2 | 46 | 290 | 178 | 139.5 | 105 | 4-19 | 2 | 18 |

| 3 | 46 | 310 | 190 | 152.5 | 127 | 4-19 | 2 | 19 |

| 4 | 52 | 350 | 229 | 190.5 | 157 | 8-19 | 2 | 24 |

| 5 | 56 | 400 | 254 | 216.0 | 186 | 8-22 | 3 | 24 |

| 6 | 56 | 480 | 279 | 241.5 | 216 | 8-22 | 3 | 26 |

| 8 | 60 | 495 | 343 | 298.5 | 270 | 8-22 | 3 | 29 |

| 10 | 68 | 550 | 406 | 362.0 | 324 | 12-25 | 3 | 31 |

| 12 | 78 | 620 | 482.6 | 431.8 | 381 | 12-25 | 4 | 34.7 |

| 14 | 78 | 720 | 533.4 | 476.2 | 412.7 | 12-29 | 5 | 39 |

進(jìn)口升降式襯氟止回閥外形尺寸--

HG/T 20592 PN10 (單位:mm)

| DN | L1 | L2 | D | D1 | D2 | Z-d | f | b | H |

| 15 | 130 | 80 | 95 | 65 | 45 | 4-14 | 2 | 14 | 82 |

| 20 | 150 | 90 | 105 | 75 | 55 | 4-14 | 2 | 14 | 82 |

| 25 | 160 | 105 | 115 | 85 | 65 | 4-14 | 2 | 14 | 98 |

| 32 | 180 | 110 | 140 | 100 | 78 | 4-18 | 3 | 16 | 110 |

| 40 | 200 | 125 | 150 | 110 | 85 | 4-18 | 3 | 16 | 118 |

| 50 | 230 | 140 | 165 | 125 | 100 | 4-18 | 3 | 16 | 138 |

| 65 | 290 | 160 | 185 | 145 | 120 | 4-18 | 3 | 18 | 156 |

| 80 | 310 | 185 | 200 | 160 | 135 | 8-18 | 3 | 20 | 160 |

| 100 | 350 | 210 | 220 | 180 | 155 | 8-18 | 3 | 20 | 185 |

| 125 | 400 | 250 | 250 | 210 | 185 | 8-18 | 3 | 22 | 208 |

| 150 | 480 | 300 | 285 | 240 | 210 | 8-23 | 3 | 24 | 245 |

| 200 | 600 | 460 | 340 | 295 | 265 | 8-23 | 3 | 26 | 298 |

| 250 | 730 | 520 | 395 | 350 | 320 | 12-23 | 4 | 28 | 342 |

| 300 | 850 | 700 | 445 | 400 | 368 | 12-23 | 4 | 28 | |

| 350 | 980 | 750 | 505 | 460 | 428 | 16-23 | 5 | 28 |

HG/T 20592 PN16

| 15 | 130 | 80 | 95 | 65 | 45 | 4-14 | 2 | 14 | 82 |

| 20 | 150 | 90 | 105 | 75 | 55 | 4-14 | 2 | 14 | 82 |

| 25 | 160 | 105 | 115 | 85 | 65 | 4-14 | 2 | 14 | 98 |

| 32 | 180 | 110 | 140 | 100 | 78 | 4-18 | 3 | 16 | 110 |

| 40 | 200 | 125 | 150 | 110 | 85 | 4-18 | 3 | 16 | 118 |

| 50 | 230 | 140 | 165 | 125 | 100 | 4-18 | 3 | 16 | 138 |

| 65 | 290 | 160 | 185 | 145 | 120 | 4-18 | 3 | 18 | 156 |

| 80 | 310 | 185 | 200 | 160 | 135 | 8-18 | 3 | 20 | 160 |

| 100 | 350 | 210 | 220 | 180 | 155 | 8-18 | 3 | 20 | 185 |

| 125 | 400 | 250 | 250 | 210 | 185 | 8-18 | 3 | 22 | 208 |

| 150 | 480 | 300 | 285 | 240 | 210 | 8-23 | 3 | 24 | 245 |

| 200 | 600 | 460 | 340 | 295 | 265 | 12-23 | 3 | 26 | 298 |

| 250 | 730 | 520 | 405 | 355 | 320 | 12-25 | 4 | 28 | 342 |

| 300 | 850 | 700 | 460 | 410 | 375 | 12-25 | 4 | 29 | |

| 350 | 980 | 750 | 520 | 470 | 435 | 16-25 | 5 | 34 |

ASME 816.5 Class150

| 1/2 | 130 | 80 | 89 | 60.5 | 35 | 4-16 | 2 | 12 | 82 |

| 3/4 | 150 | 90 | 98 | 700 | 43 | 4-16 | 2 | 12 | 82 |

| 1 | 160 | 105 | 108 | 79.5 | 51 | 4-16 | 2 | 12 | 98 |

| 1 1/4 | 180 | 110 | 117 | 89.0 | 64 | 4-16 | 2 | 13 | 110 |

| 1 1/2 | 200 | 125 | 127 | 98.5 | 73 | 4-16 | 2 | 15 | 118 |

| 2 | 230 | 140 | 152 | 120.5 | 92 | 4-19 | 2 | 16 | 138 |

| 2 1/2 | 290 | 160 | 178 | 139.5 | 105 | 4-19 | 2 | 18 | 156 |

| 3 | 310 | 185 | 190 | 152.5 | 127 | 4-19 | 2 | 19 | 160 |

| 4 | 350 | 210 | 229 | 190.5 | 157 | 8-19 | 2 | 24 | 185 |

| 5 | 400 | 250 | 254 | 216.0 | 186 | 8-22 | 3 | 24 | 208 |

| 6 | 480 | 300 | 279 | 241.5 | 216 | 8-22 | 3 | 26 | 245 |

| 8 | 600 | 460 | 343 | 298.5 | 270 | 8-22 | 3 | 29 | 298 |

| 10 | 730 | 520 | 406 | 362.0 | 324 | 12-25 | 3 | 31 | 342 |

| 12 | 850 | 700 | 485 | 432 | 381 | 12-25 | 4 | 34.7 | |

| 14 | 980 | 750 | 535 | 476 | 412.7 | 12-29 | 5 | 39 |

進(jìn)口浮球式襯氟止回閥外形尺寸--

HG/T 20592 PN10 單位:mm

| DN | L | D | D1 | D2 | Z-d | f | b |

| 15 | 130 | 95 | 65 | 45 | 4-14 | 2 | 14 |

| 20 | 150 | 105 | 75 | 55 | 4-14 | 2 | 14 |

| 25 | 160 | 115 | 85 | 65 | 4-14 | 2 | 14 |

| 32 | 180 | 140 | 100 | 78 | 4-18 | 3 | 16 |

| 40 | 200 | 150 | 110 | 85 | 4-18 | 3 | 16 |

| 50 | 230 | 165 | 125 | 100 | 4-18 | 3 | 16 |

| 65 | 290 | 185 | 145 | 120 | 4-18 | 3 | 18 |

| 80 | 310 | 200 | 160 | 135 | 8-18 | 3 | 20 |

| 100 | 350 | 220 | 180 | 155 | 8-18 | 3 | 20 |

| 125 | 400 | 250 | 210 | 185 | 8-18 | 3 | 22 |

| 150 | 480 | 285 | 240 | 210 | 8-23 | 3 | 24 |

HG/T 20592 PN16

| 15 | 130 | 95 | 65 | 45 | 4-14 | 2 | 14 |

| 20 | 150 | 105 | 75 | 55 | 4-14 | 2 | 14 |

| 25 | 160 | 115 | 85 | 65 | 4-14 | 2 | 14 |

| 32 | 180 | 140 | 100 | 78 | 4-18 | 3 | 16 |

| 40 | 200 | 150 | 110 | 85 | 4-18 | 3 | 16 |

| 50 | 230 | 165 | 125 | 100 | 4-18 | 3 | 16 |

| 65 | 290 | 185 | 145 | 120 | 4-18 | 3 | 18 |

| 80 | 310 | 200 | 160 | 135 | 8-18 | 3 | 20 |

| 100 | 350 | 220 | 180 | 155 | 8-18 | 3 | 20 |

| 125 | 400 | 250 | 210 | 185 | 8-18 | 3 | 22 |

| 150 | 480 | 285 | 240 | 210 | 8-23 | 3 | 24 |

ASME 816.5 Class150

| 1/2 | 130 | 89 | 60.5 | 35 | 4-16 | 2 | 12 |

| 3/4 | 150 | 98 | 70.0 | 43 | 4-16 | 2 | 12 |

| 1 | 160 | 108 | 79.5 | 51 | 4-16 | 2 | 12 |

| 1 1/4 | 180 | 117 | 89.0 | 64 | 4-16 | 2 | 13 |

| 1 1/2 | 200 | 127 | 98.5 | 73 | 4-16 | 2 | 15 |

| 2 | 230 | 152 | 120.5 | 92 | 4-19 | 2 | 16 |

| 2 1/2 | 290 | 178 | 139.5 | 105 | 4-19 | 2 | 18 |

| 3 | 310 | 190 | 152.5 | 127 | 4-19 | 2 | 19 |

| 4 | 350 | 229 | 190.5 | 157 | 8-19 | 2 | 24 |

| 5 | 400 | 254 | 216.0 | 186 | 8-22 | 3 | 24 |

| 6 | 480 | 279 | 241.5 | 216 | 8-22 | 3 | 26 |

進(jìn)口襯氟止回閥典型應(yīng)用--

進(jìn)口襯氟止回閥可承受除熔堿金屬和元素氟以外的酸、堿、鹽、氯、王水等各種強(qiáng)腐蝕性介質(zhì),廣泛應(yīng)用于化工、石油、醫(yī)藥、食品、鋼鐵、冶煉、造紙、電力、環(huán)保等腐蝕性嚴(yán)重的場合。